The greater the number of machines, systems and devices, the more difficult it becomes to keep track of them all. What is my machine’s status? Where was a threshold exceeded and how can the problem be fixed?

Intelligent condition monitoring and alerting can provide you with this information at a glance. Our IoT framework gives you the building blocks you need to configure monitoring rules and integrate them into your system landscape quickly and easily. If incidents accumulate or threshold values are exceeded, alarms are automatically triggered.

The result: Service and maintenance are only carried out when truly necessary. Failures and downtimes of your machines are significantly reduced, and overall productivity is increased.

Thanks to its IoT platform, Feintool has access to machine data for Condition Monitoring. This allows for significant reductions in maintenance and service technician inspections. Defects can be identified and addressed before the machine breaks down.

Using the IoT solution developed for Costa Express, the status and use of all coffee machines can be viewed and managed centrally. The machines are able to report problems directly within the platform, making diagnosis and problem solving quick and easy.

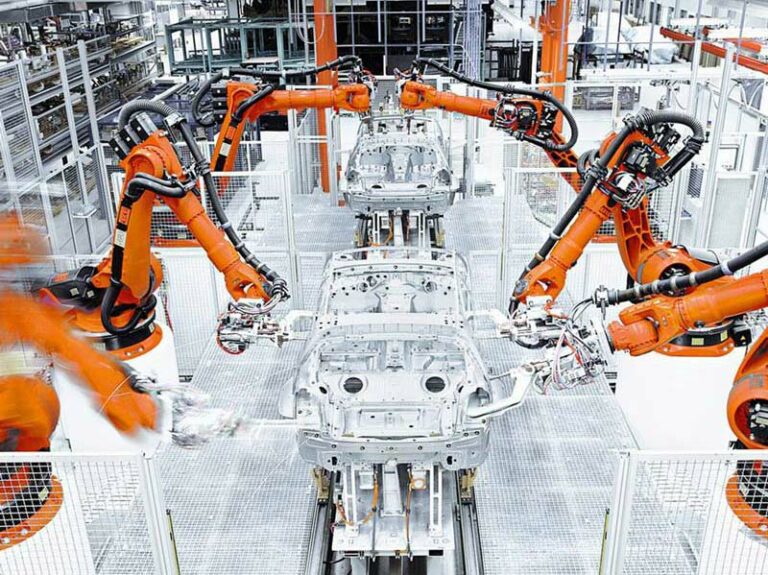

The cloud-based software solution iiQoT developed by Device Insight maximizes the uptime of KUKA’s robot fleet. Functions and services such as Condition Monitoring, visualization and troubleshooting of robot systems are much more efficient with iiQoT.

The real added value of an alert only emerges when data analysis and the triggering of alerts, alert management and meaningful actions are linked together. With our Alert Engine, we are able to deliver a holistic solution concept that can be adapted to your individual operational processes.

Arrange an initial consultation without obligation.

Delivering excellence in IoT. We are an IoT Solution Provider for Smart Products, Connected Vehicles, Smart City, Smart Energy and Smart Production.